Weight filling maintains a superior texture for sauces and dressings, especially low-fat types

Beyond taste, manufacturers pay particular attention to texture and appearance as they are key elements for a satisfied consumer experience. However, maintaining the original state of the product throughout the packaging process can sometimes be a technical challenge due to the specific rheology of sauces. This is particularly true for low-fat emulsions (mayonnaise or others), which are more delicate than traditional recipes. The crucial point that is true for any emulsified sauce is that dynamic forces applied to the product must be reduced to a minimum. This is where weight filling offers true benefits.

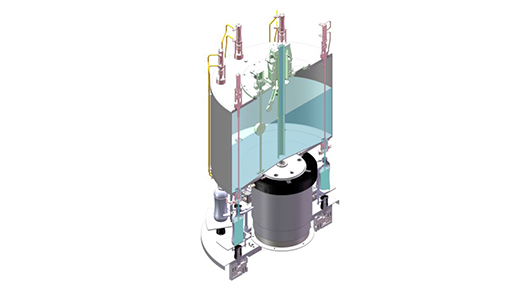

Weight filling assisted by overpressure for highly viscous products

Weight filling technology

The weight filling technology is based mainly on gravity or assisted by a light overpressure for highly viscous products. The sauce is not strongly forced into the filling unit, as is the case with volumetric filling where the product suffers a double intake and down stroke to get in and out of the dosing chamber, or with flow metering where it has to be pressurized to pass through a flow meter and the narrow tubes. To the contrary, weight filling uses a gravimetric tank, where the product load is maintained at a constant level, ensuring a linear and regular flow which reduces viscosity loss.

The product circuit is also much simpler with weight filling than with volumetric filling. The sauce is piped out of the process into a small buffer tank and then poured into the container, all this with no dynamic seal and very few moving parts. It thus generates almost no turbulence in the product.

Dry decontamination of the packaging just before weight filling

Naturally clean, weight filling makes it easier to prevent pathogen growth in sensitive recipes

Health has long been a major concern for consumers and this is evident by their willingness to pay a premium price for natural products. The health conscious consumer has driven manufacturers to develop new recipes, with low salt and preservative content, which are more sensitive to pathogen growth.

Of course, any alteration of this kind requires a new look at the whole packaging process from a microbiological point of view. Particularly sensitive recipes might, for example, require specific options such as packaging dedusting or packaging decontamination.

Weight filling is a naturally clean technology. This is one of the unique selling points which is clearly demonstrated when looking at the filling nozzles: fully opening and 100% self-draining, they remain perfectly clean throughout the filling process. Moreover and unlike volumetric filling, the filling valves never touch any container, which avoids any contamination.

Taking a closer look at a typical weight filling unit proposed by Serac, one can see that the whole product circuit is designed with easy cleaning in mind. It involves no joints or gaskets that are hard to clean and subject to wear, but employs metal to metal valves with extremely clean closure and very few mechanical parts in direct contact with the product. It is very easy to clean, especially with efficient CIP equipment. Those proposed by Serac work in a closed sanitation circuit and make use of multidirectional sanitary spray balls for a higher impact of the liquid jets. Tanks are 100% self-draining, convexed shaped with no dead corners, fully inspectable and suitable for swab tests.

Easy conversion with weight filling between different packaging shapes and sizes

Weight filling allows optimizing productivity on extended ranges of sauces

The range of sauces proposed in outlets is exploding, due to consumers seeking new varieties (especially ethnic sauces that allow them to easily prepare their favorite exotic dishes at home) and packaging tailored to their needs, from single person households to large families.

In order to be able to offer the product variety required by consumers, manufacturers need to find the most flexible equipment and to optimize changeovers.

Weight filling is a particularly versatile technology, as far as the nature of the product is concerned. It is adapted to hot (60-80°C) and cold preparations, as well as non-conductive, aerated or non-homogenous products, which is not the case for inductive and mass flow metering. The technology is also more flexible in terms of packaging, since it can accommodate a 1 to 20 ratio whereas volumetric filling is limited to a 1 to 6 ratio. With this double flexibility in hand, it is possible to design a line that will be able to fill up to 20 recipes in different packaging sizes, as Serac recently did.

Of course, such a complex project can only be profitable if changeovers are fully optimized. And this is again an argument for weight filling. As explained earlier this technology is naturally clean process. It also provides the simplest product circuit, which saves time and product at the end of each batch when draining as well as time and water on cleaning operations. Weight is also the easiest parameter to calibrate when products show different physical characteristics. Production setup is thus much simpler with weight filling than with other technologies. Another time savings benefit.

Gentle, clean and flexible, weight filling is definitely a technology that manufacturers of sauces and dressings should consider if they are planning on increasing their production of low-fat and preservative free products or on diversifying the number of recipes that will go through their packaging line.